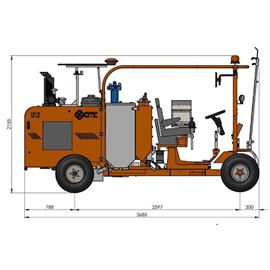

98:2 Application

98:2 systems are available in different variants:

Open - means that the spray plastic (98 %) is also mixed with the hardener (2 %) jet in jet. The liquid hardener is sprayed into the spray plastic using a low-pressure system. The advantage of this is that you can stop the machine at any time without anything hardening in the system. The disadvantage is that it is difficult to visually check whether hardener has been injected.

In the closed system, paint and hardener are combined in a mixing chamber. The advantage lies in the electronic monitoring of whether enough spray plastic and hardener are actually mixed. The disadvantage becomes apparent when the machine is stopped frequently and for long periods. In this case, the mixing chamber, hoses and nozzles may have to be freed (rinsed) of activated material more often.

Open - means that the spray plastic (98 %) is also mixed with the hardener (2 %) jet in jet. The liquid hardener is sprayed into the spray plastic using a low-pressure system. The advantage of this is that you can stop the machine at any time without anything hardening in the system. The disadvantage is that it is difficult to visually check whether hardener has been injected.

In the closed system, paint and hardener are combined in a mixing chamber. The advantage lies in the electronic monitoring of whether enough spray plastic and hardener are actually mixed. The disadvantage becomes apparent when the machine is stopped frequently and for long periods. In this case, the mixing chamber, hoses and nozzles may have to be freed (rinsed) of activated material more often.